The applications for various plastic parts are endless and almost every industry relies on plastic in some way – and for good reason. Plastics are both incredibly strong and very versatile and as such are used in the manufacture of various parts that can be used in everything from the automotive industry to the medical sector.

There is a plethora of methods that can be utilised when manufacturing plastic parts, however, two of the most popular are; vacuum forming and injection moulding. Both processes offer unique benefits and drawbacks and ultimately depend on the specific plastic part that needs to be manufactured.

Many businesses, however, do not know the difference between the two processes and often chose the wrong manufacturing technique for their plastic parts.

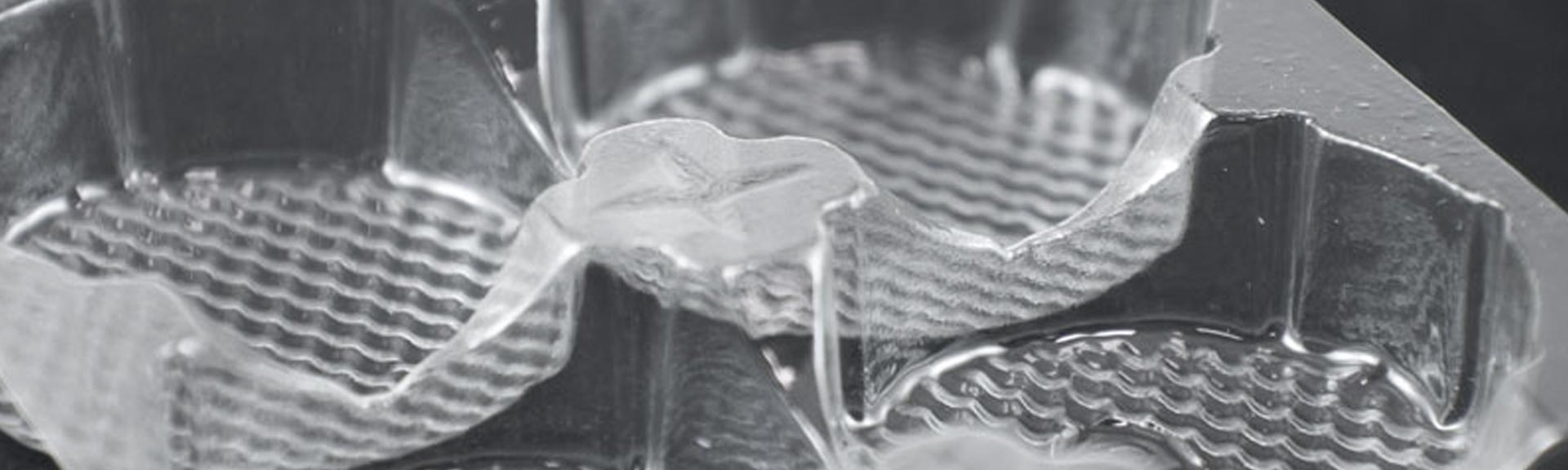

Vacuum forming (also referred to as thermoforming) is the process of forming heated plastic sheets to the surface of a specifically designed mould. Vacuum forming is one of the oldest and most common methods of processing plastic materials.

The process of vacuum forming starts by heating a plastic sheet until this becomes soft and flexible. It is then placed over a mould and a vacuum of air is then applied against the sheet in order to stretch the sheet over the mould, this then creates the specific design.

Once this has been completed, the newly moulded plastic is then cooled and ejected from the mould ready for any trimming. At this stage, any excess plastic is removed, and sharp edges are sanded down so they are smooth and safe for consumer use.

Vacuum forming has its own unique benefits which, in most cases, can make it more of a viable option as opposed to other types of plastic forming, including injection moulding. Some of the benefits of vacuum forming include:

However, as with most plastic forming services, vacuum forming does have its drawbacks which can, in a few cases, make other plastic forming methods more suitable. The drawbacks of vacuum forming include:

Vacuum forming can produce a wide range of products for a variety of sectors, such as the automotive, aerospace and medical industries. Here are some of the most popular products made by this process:

Injection moulding is a more complex manufacturing technique than vacuum forming and can require high levels of engineering expertise.

The first step of this process is to create the mould itself; these are usually made from metal. Secondly, polymers are heated into molten form and this liquid polymer is then injected into the metal mould.

After being injected into the mould, the plastic liquid is held in place until this has cooled and formed to the shape of the mould. Once formed, the mould is opened, and the finish plastic parts are removed.

Injection moulding has many benefits, such as:

However, injection moulding does have its drawbacks which can make vacuum forming the favoured process especially where low cost and short lead times are imperative. The drawbacks of injection moulding include:

The main drawback of injection moulding, however, is that it is heavily reliant on the correct design and manufacture of the mould itself. This means that any discrepancies in the mould could result in an incorrect or faulty product being manufactured.

Injection moulding can produce a range of products for a variety of sectors, such as the medical and agricultural industries. Here are some of the most popular products made by injection moulding:

It is apparent that both methods have their strengths and weaknesses and knowing these is the first step in deciding which manufacturing technique will be best for your plastic parts and, ultimately, the method in which you choose will depend on the part you need.

In order to determine which method is best it is imperative that you consider the following questions:

Based on these questions it is likely that vacuum forming will be the best and most viable option as it has lower set-up costs, shorter lead times and is able to produce fairly large quantities of products.

In addition vacuum forming is more flexible than injection moulding and whilst extra finishing may be required to get the right colours or texture vacuum forming is often seen as a better alternative to injection moulding.

Here at Ansini offer an extensive and professional vacuum forming service suitable for making plastic parts for a variety of sectors. Please feel free to get in touch with our team for more information about our vacuum forming services.

If you have a question for us, or would like to discuss a specific project, please do get in touch.