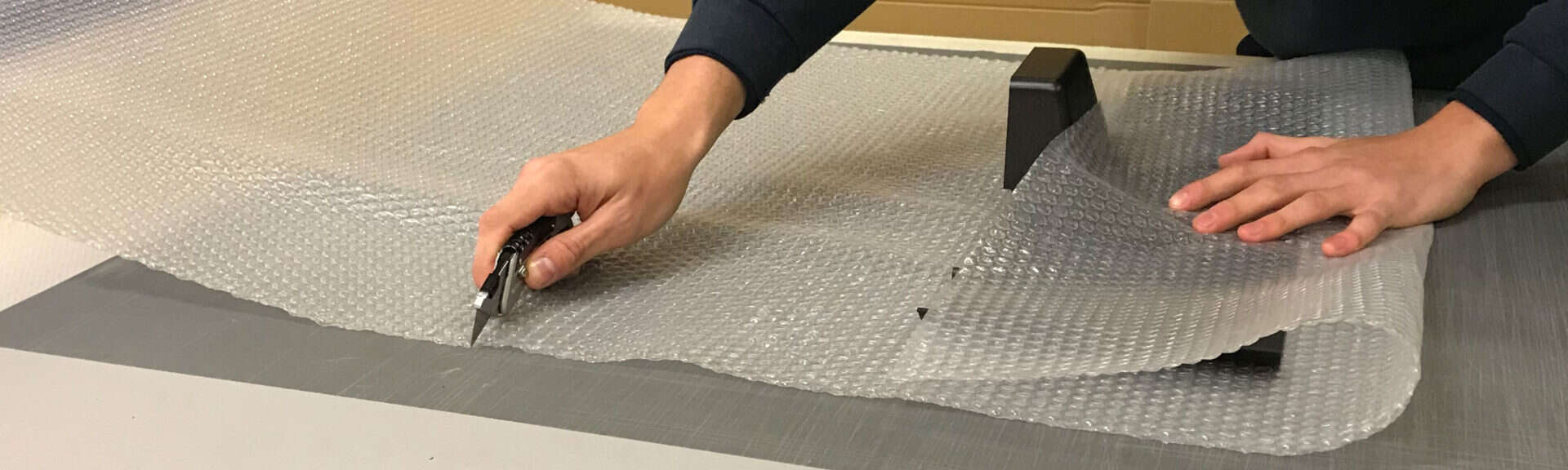

We understand that packaging is an extremely important part of the delivery process if the integrity of a product is to be maintained. This is why we work closely with our clients to determine a best-practice solution which will ensure products arrive on time, undamaged and ready for use or long-term storage. Involving us at the product design stage will further ensure the development of the correct packaging.

Make to print plastic components are where they are designed, materials specified and tested by your company. The supplier only becomes involved solely to manufacture the products to the specification requested and will have no other input on the design or testing of the plastic components.

The make to print process is suitable for a variety of plastic parts which can range from small mass produced pieces to larger, more unique projects. Our make to print parts can be manufactured through the vacuum forming or thermoplastic forming process.

Furthermore, our make to print plastic components are finished to a high standard by one of our eight, industry-leading, Maka 5 Axis CNC machines which can meet even the most complex machining and trimming requirements.

If required, full inspection is carried out on all components throughout the entire manufacturing process, with the final inspection prior to packaging and dispatch being carried out in accordance to ISO 9001:2015.

If you have a question for us, or would like to discuss a specific project, please do get in touch.